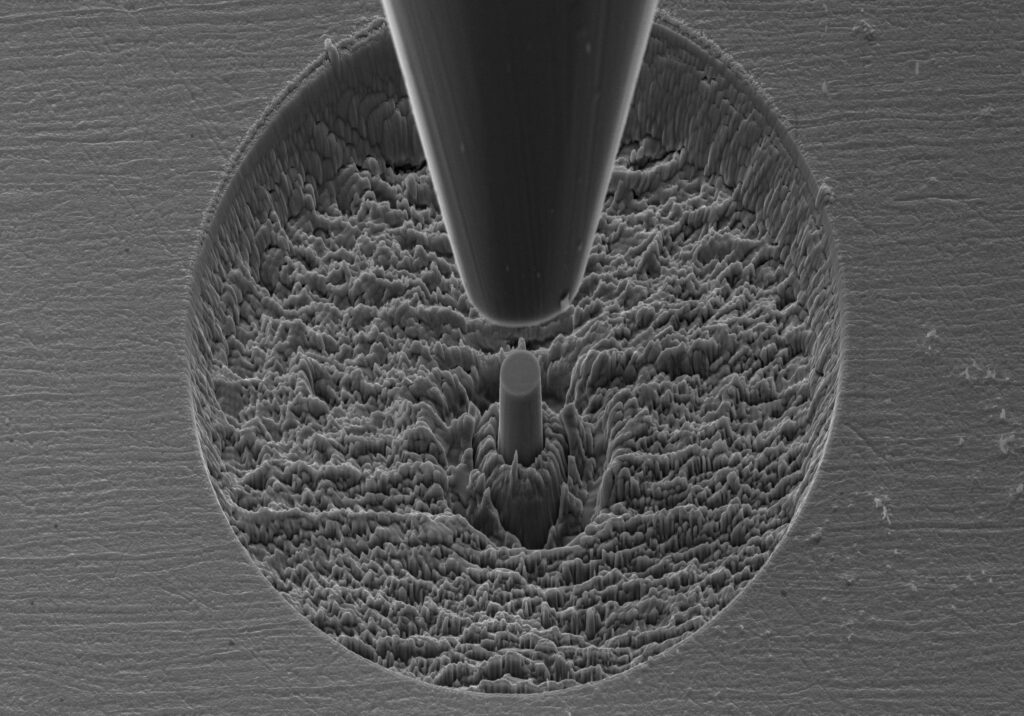

With the in-chamber nano-indentor attachment, SSW staff along with engineer Konrad Mazurkiewicz, are squishing tiny micron sized pillars of metal inside of Dr. Moser’s (Earth Sciences) FE-SEM… live, while we watch! These are in-situ experiments that are actually occurring inside the SEM. Typically people just use the SEM to observe things, and we’re actually doing experiments inside the SEM!

|  |

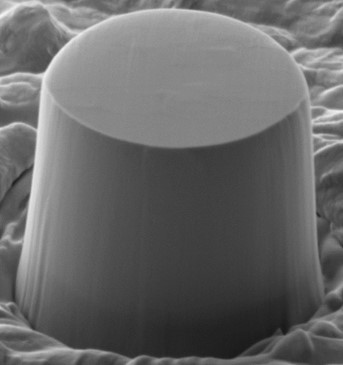

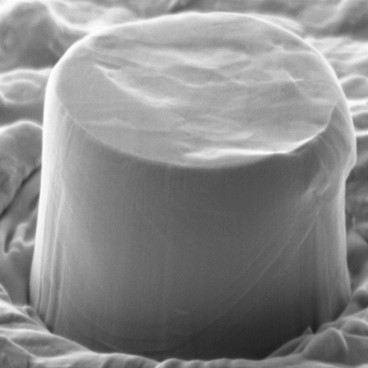

| Before Compression | After Compression |

We are testing the micromaterial properties of the metal alloy Zirconium containing 2.5% Niobium. This alloy is used in the pressure tubes of the Canadian designed CANDU nuclear reactors, of which there are 18 in Ontario and 34 worldwide. These pressure tubes have non-enriched fissile Uranium fuel bundles pass through them, and along with the presence of heavy water, produce the heat needed to generate electricity. Note that over 50% of Ontario’s energy is derived from Nuclear energy – carbon emissions free! Through compression of these micropillars (sized 2 microns squared – an average human hair is 50 microns in diameter!), we can observe the mechanisms of deformation involved when the alloy is subjected to great stresses, it also allows us to quantify the material properties on the micro scale, and to ultimately generate a comparison between these properties when the material is subjected to the effect of irradiation hardening incurred over a lifetime of operation inside a nuclear reactor.